Pair

Valve (Secondary Air System) Removal Made Easy

|

| by "Moccasin" Mike |

| ********************************************************* |

For the

C90 Boulevard

Click here for

printable Text Only Instructions

Many thanks to my friend Bill Schmahl "Geesh" for the wonderful photographs and

technical help in preparing these instructions!

Click here to see a shot of Bill's gorgeous Naked Bully Jugs!

NOTE** The only tools you will need for

this operation are a pair of pliers, a 6mm hex (allen) wrench,

a phillips head screwdriver and a 10mm wrench. These can be found in your Suzuki Tool Kit. (Add

a second 10mm wrench if you plan to remove the cylinder studs).

This procedure will take about an hour if you work real slow. J

All metal components of the removal kits have been "Blackened"

with satin finish engine paint, and baked at 400 degrees to match

your engine block.

|

The chrome cover is held in place by two allen head

bolts. Your bolts may have button caps covering the allen sockets, if so,

use a sharp pointed knife to pry the chrome button

cap off, then use a 6mm hex (allen) wrench to remove the screws, and pull

the cover. |

|

| STEP 2. CLAMPS,

NUTS, BOLTS, AND VALVE. |

|

With a pair of pliers loosen and slide the

upper tube hose clamps toward the center of the rubber tubing, and pull the

two rubber tubes from the pair valve body. |

|

| If you only wish to disable the pair

valve, but not remove any of it's components, insert round head screw

or golf tee

upside down into each lower rubber tubing piece. leave a

small piece of the threaded or pointed end sticking out of the the top of the

rubber tube (for removal later if necessary), and re-install the

tubes to the pair valve and replace the cover. For a visual reference for disabling the system

without removing components, CLICK HERE. |

Continue with Removal |

|

With a 10mm wrench, remove the lower tube flange nuts from

each cylinder. (4 nuts total) Now you can easily slip the metal tubes off

the cylinder studs.

Make sure that no gasket material remains on the cylinder

flanges. |

Rear Metal Tube & Flange Front Tube & Flange

|

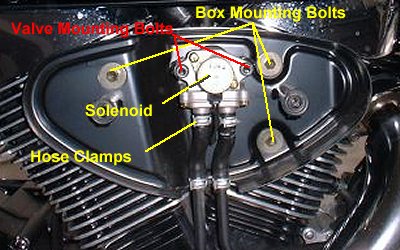

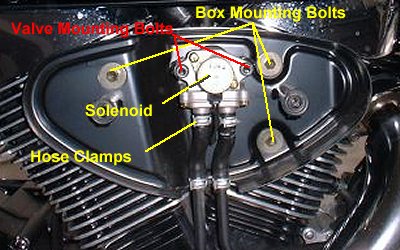

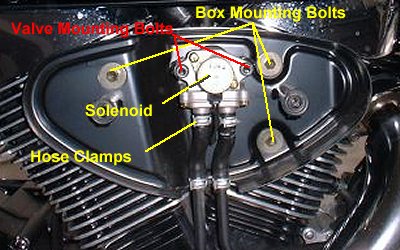

Loosen but do not remove the two small Phillips screws

holding the solenoid to the pair valve body..

Remove the three 10mm Box Mounting Bolts. |

|

| |

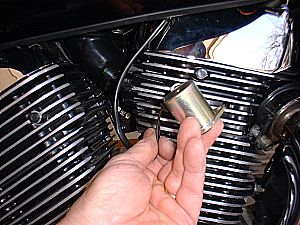

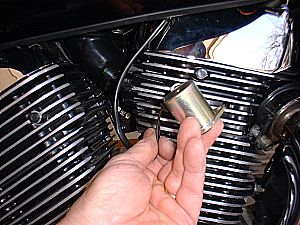

| Holding the box loosely away from the engine, reach behind

it and pull the rubber air hose loose, either from the back of the valve

body or from the metal connecting adapter just under the side panel (fake

tank panel). (metal connecting adapter shown at right) |

|

| Now disconnect the electrical solenoid connection just under

the side panel and remove the box and pair valve as a unit. |

|

| Pull the remaining section of rubber air inlet hose free

from the bottom of the air filter box, paying close attention to where it

comes from, then cap the air box outlet nipple with the larger of the two

rubber caps from the removal kit. Its a good idea to use the retaining clip

on the rubber cap, but you may need to compress it a bit beforehand to give

it a snug fit. |

|

| Remove the two gold colored Phillips head solenoid mounting

screws, then pull the solenoid and its wire pigtail free from the valve body

and box, feeding the wire through from the back of the case as you pull . |

|

| Reconnect the solenoid to the bike's connector, and use the

two supplied plastic zip ties to secure it up out of site, behind the side

panel. This can be done by looping the zip ties over the main wiring harness

and through the solenoid screw holes, then cinch them up to the main

harness. |

|

NOTE:

An alternative to retention of the solenoid is replacing it with a 4.7k-Ohm

1/4 Watt inline resistor. You can learn more about that

HERE. |

|

| STEP 3.

BLOCK THE CYLINDER PORTS |

Using the gaskets and plates from the kit, cover the two

cylinder ports. Some people prefer to use a little high temp gasket sealer on

the gaskets, but it is not a necessity. You may secure the plates to the

cylinders using the existing nuts that were removed earlier (and lock washers

from the kit), or for a slightly cleaner (but a bit risky) look, you can remove

the studs from the cylinders and use the four supplied M6-1.0x16mm (long)

bolts and lock washers. See stud option note below.

| STEP 4. PLUG THE

SCREW HOLES |

Use the three supplied M6-1.0x10mm (short)

Stainless Steel bolts and lock washers to fill the empty holes in

the cylinders left by removing the housing.

YOU’RE DONE!! Donít you wish YOU could loose five pounds

of ugly fat that easy!!!

NOTE* There are an additional four M6-1.0x16mm

Stainless bolts and washers supplied with the kit. These are for

replacing the cylinder studs, if you desire to do so.

REPLACING STUDS: If you haven’t pulled

studs before; thread two nuts on the stud and tighten them very

tightly against each other (opposite directions toward each other),

then put a wrench on the inner nut, and as you try to "unscrew"

it, the whole stud will unscrew. You may have to apply a little

"counter pressure" to the outside nut with another

wrench at the same time.

CAUTION! - Bear in

mind that anytime you work with studs, you run the risk of

breaking the stud off, requiring difficult drilling and tapping

to replace it. Pre-soaking the threads with penetrating oil, and

a few light taps straight on the end of the stud with a light

hammer will help break loose the hold of any corrosion inside. If

the stud seems to require a lot of force, leave it be!

Use your "Back" button or

Click HERE

to go back