Decomps

for Dummies

|

The

SIMPLE way to optimum decomp starting

performance

|

|

For decades, the motorcycle industry has enjoyed the

monetary benefits of making bikes APPEAR to be more

complicated than the average shade tree mechanic can

manage. This helps maintain a generous flow of traffic to

the Service Department of your local dealer, where the

technicians know all the shortcuts and tricks of the

trade, to make life easy and the bosses happy.

Enter the dreaded Decompression adjustment procedure for

the LC Intruder!! Ever read the manual on how to adjust

these things? AARRGGHH!!! Visions of major oil spills,

parts strewn all over the property, and a basket case

engine that will never run again!! Quick! Load her up and

haul her to the shop for this one!!! NOT!!

The Factory Service Manual shows how to initially setup the Decomp

system on a brand new factory assembly. It never goes beyond that point

to explain how to actually tweak them for the individual bike, so once

you know how to get TO the adjustment points, put the manual away.

Decomps have a very simple job of reducing compression inside the

cylinder by slightly lifting the exhaust valves. When engines are so big

that they require more power to turn over than the starter and battery

are capable of, the use of decomp valves cams is preferable to beefing

up the electrical components. If your starter and battery are good, but

are having trouble spinning your engine over, there's too much

compression fighting against them. While this condition is often found

in the rear cylinder (because of the weak cable system of linking the

decomps together), it is possible to have either or both of the

cylinders causing the trouble, so adjustment is a two-step

procedure. First you make adjustments to the rear lobe to insure that

both lobes move at precisely the same time, then you adjust the WHOLE

SYSTEM by tightening or loosening the front lobe cable at the solenoid,

until the starter doesn't have to work so hard.

Because the ideal setting for decomps is achieved by sound,

and not something you can measure with a stick and take a picture of, I

could type for days and it wouldn't make any difference. It isn't rocket

science, just make sure they both move at the same time, then make sure

they both open up enough for the engine to spin without a lot of work.

It took me longer to type this than it does to actually fix your

decomps.

Realistically, diagnosing the problem behind a bike

that won't start, can be a frustrating experience, as

there are many potential problems that can create the

same symptoms. Here are a couple of guidelines to help

determine the root of a "labored" starting

problem, and by "labored", we mean that the

starter motor kicks in and attempts to turn the engine

over, but either can't get it over the "hump",

or does so with a lot more effort than usual.

If your battery is over two years old, and you CONSISTENTLY

have a labored start, then the first suspect will be the

battery.

If she starts cold with no problems, but CONSISTENTLY

has labored starting while hot, then the charging system

should be checked. A grounding rectifier can actually

discharge your battery while you ride. The battery can

somewhat recover while sitting, so it may well start the

bike while its cold, but then not be able to start it

after only a few miles of riding.

If everything on the bike seems to be in perfect order,

and you OCCASIONALLY have a labored

start, or no-start, for no apparent reason, and with no

perceived pattern, then very likely, the rear decomp cam

is loose or lagging behind. A good test for this is to place the bike in

second or third gear when it won't crank, and push it

backwards a few inches while in gear, then try again. If

it starts then, you definitely have a loose rear cam.

Pushing the bike backwards while in gear moves the rear

piston back off its compression stroke enough to give the

system a running start at it when you push the button.

This will only happen when the rear cylinder stops on its

compression stroke. Therefore, it seems impossible to

predict when it won't start. Might be cold, might be hot,

might only happen once today, but maybe three times

tomorrow...This occasional no-start is

the prime indicator that the problem lies with the rear

decomp cam. (If the front cam were out of adjustment, it

would NEVER start properly, as both cams would then be

off their specs.)

The rear cam is actuated via a cable from the front

cam. This cable makes an "S" turn along its

path and its metal sheath is lined with nylon, for a

smooth action. Unfortunately, due to the pressure on it

during actuation, it tends to cut its way into the inner

nylon lining, leaving it with ever increasing slack. Once

the slack occurs, the rear cam moves slightly behind the

action of the front cam and does not open up quite as

much. It only takes a tiny bit of slack in the cable to

render the starting system incapable of turning over the

rear cylinder.

Therefore, the REAR CAM CABLE is the weakest link in the

entire decompression system, and it is more than likely

the culprit behind your occasional no-starts.

The decomp cams are located right

beside the spark plugs, so in order to make

adjustments, you will need to "skin"

the LC down for spark plug replacement (see

"Skinning the LC")

|

|

|

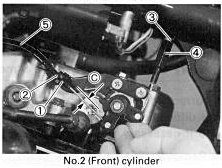

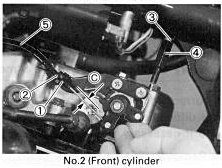

Adjustment of the rear cam is made at the right of the front

cylinder. On the right photo above, items 1 and 2 are the adjustment

nuts used to tighten or loosen the cable to the rear cam.

To tighten the rear cam you simply loosen the lock nut on

the front end of the cable bracket, then turn the

adjuster on the back end of the bracket counter clockwise

to back it away from the front cam, then secure the

adjustment with the lock nut on the front.

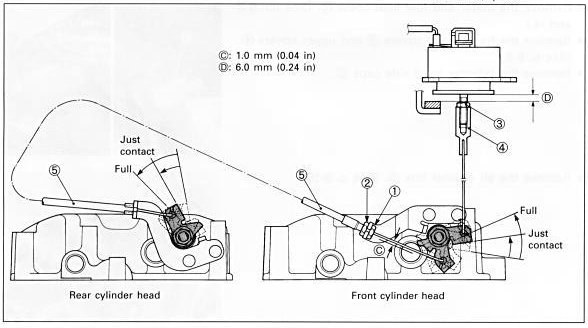

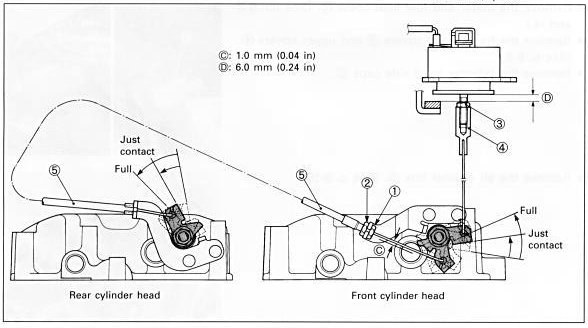

With the front cam resting on its stop plate, tighten the

rear cam adjustment until the rear cam lifts from its

stop plate, then loosen it back up until it just touches

the stop plate. Secure the front lock nut, and visually

check to ensure that the rear cam moves at precisely the

same time as the front one. Any slight delay in "lift

off" between the two cams means the rear valve is

not opening as much as the front valve. They should be

perfectly in sync.

Now, pull both spark plug wires from the plugs, and hit

the starter a few times to make sure all is well. If

starting is still "labored" a very slight

adjustment of the front cam may be in order, but this is

rarely ever needed.

Important note: The stop plates

for the cams are used only as a fixed reference for synchronizing the

two cams. You may need to loosen your front cam to get it to rest on the

stop temporarily, but final adjustment and distance from the stop plate

will depend on the wear factor on your bike. On a used bike, there is no

set amount of space or play, just whatever it takes to make the system

function properly.

Items 3 and 4 in the right photo above are used to

adjust the front cam. It is very unusual for the front

cam to get out of adjustment, due to the very short and

direct cable routing to it. If the solenoid is working,

it will not lose retraction depth, that cable will not

stretch, and there is no cable sheath to wear. High

mileage engines might be the exception here, as the cam

lobe can possibly eventually wear to some degree. If the

cable adjustment lock nut has not come loose, and no

major repair work (requiring removal of the solenoid) has

been done, the front cam is likely still set properly.

If you feel that the front

cam needs adjustment (which adjusts BOTH decomps at the same time), its easier to do trial and error

adjustment than to actually set it to specs. Adjust the

FRONT cable (that goes straight to the solenoid) by one half turn at a time, then hit the starter (plug

wires off but plugs still in) and listen. If the engine spins too easy,

as if there are no spark plugs in, the decomps are too tight. If it is

labored or won't turn over at all, they are

too loose! The trick is to find a happy medium so that the battery and

starter aren't working so hard to spin the motor. (after a couple of

revolutions, the decomps automatically disconnect to give the bike full

compression) This procedure beats the heck out of pulling

the generator cover and locating TDC, then trying to

measure free play in a difficult area to access.

|

The Decompression system is nothing more than a pair

of cheater cams that lift the exhaust valves slightly

during starting, to ease the burden on the starter and

battery. They are actuated by a single large electrical

solenoid that retracts the cams when you push the starter

button. The solenoid (upper right in the photo above) is

cabled to the front cam lever, and it in turn is cabled

to the rear cam lever. Pull the front cam and the back

one pulls with it.

The exhaust valves are only opened a very slight amount,

as too much retraction would leave insufficient

compression for the engine to run with, so there is a

very fine line between to much decomp and not enough. Too

much retraction and the engine will spin over like

somebody left the spark pugs out. Not enough retraction

and you will think you have a dead battery!

The trick to working with decomp adjustment is to make

sure that you really DON'T have a dead battery first!!

|