Adding a Harley

Style Ignition Switch

|

Replace your OEM

ignition with the rider friendly HD flip top switch!

|

|

Sometimes Motorcycle Design Engineers like to have a little fun and

locate the ignition switches in hard to reach places, just so they can

snicker when you fall over reaching for the keys, or they place

ignitions so close to body parts that your keys will damage the finish

on your gorgeous bikes. For years some of the larger Harley bikes have

incorporated a flip top style switch and located it on the top of the

console or fuel tank for easy, instant access. These switches do not

require the use of an ignition key to operate, but they have a hidden

ignition lock underneath the flip up top cover, so you can LOCK your

ignition when away from the bike. This design not only carries a clean,

custom look, but it keeps dirt and water out of the key slot to reduce

corrosion problems.

The LC Intruder has a perfect location for the adaptation of an HD

style switch, right in the fuel door! Now, before you go thinking "Kaboom!"

and having visions of mushroom clouds, consider the fact that the LC

vents its fuel tank up under the air box covers via a carbon canister,

well away from the fuel door area. The fuel cap is only inward vented

and vapors cannot escape into the fuel door area once the cap is on.

Also consider that there are no exposed contact points on the new

ignition switch to cause a spark, and if that ain't enough to ease your

concern, you can always silicone seal the underside of the switch once

its installed.

Of course, this is no guarantee that there may not possibly be a

threat of danger involved, and I encourage you to proceed at your own

risk. To date, I have never heard of any problems with this

modification, but that doesn't mean there haven't been any. ;-) Do it if

it feels good, but do it at your own risk.

|

Click the Photos for Larger Format |

1. Remove the seat by taking the two front bolts, and the two back

allen head bolts off, there by exposing the wire connector we will be

dealing with. Then remove the fuel door by unlocking it and removing the

two phillips head screws.

2. Locate, on the left side of the fuel filler tube, the ignition switch

wires it is a small square connector with 5 wires protruding from either

side. The color of the wires are Red, Orange, Orange with a

Yellow tracer, Gray, and Brown.

|

|

Remove the

original switch by removing the one allen

head screw located on top of the switch

and removing by pulling, carefully by the switch.

3. Once the switch is removed, cut all 5 wires about half way between

the switch and the connector, discard the old switch. The Gray and Brown

wires are your running and tail lights, the lights are wired on a loop and don't need to

be connected to the Ignition, but most models will require that they be

at least connected to each other for this mod, so strip a bit of

insulation off and twist these two wire ends together and tape

them up. Now your done with two of the 5

wires.

Note! Most later

model bikes require that the grey and brown wires be connected

to each other. Before you finish the

project, check all running lights and tail lights for operation.

If they aren't working, you may need to tap the brown and/or

grey wire to a power source, such as the orange wire from the

ignition switch.

|

|

4. Now were

going to start wiring. At this point you will need a Resistor,

available from Radio Shack, part # 271-1311, 100-ohm, 1/4 watt

5% tolerance.

|

And the heart of this operation, a Harley type switch.

I used a Drag Specialties part # DS-272187, Side Hinge Ignition Switch 93-00.

Cost about $30.00 including shipping.

|

|

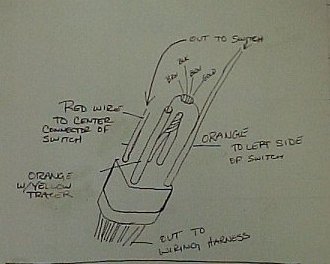

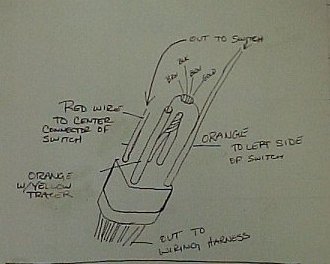

Strip back the insulation on the Red, Orange, and Orange W/ Yellow

Tracer wires. Solder a resistor from the Orange w/Yellow to the Orange

wire, connect a 10" section of 16ga. wire to the red wire and a 10"

section to the Orange wire, and attach a connector at the end of each to

attach to the new switch

set the new wire connector to the side.

(The two wires in the background are your grey

and brown wires)

|

|

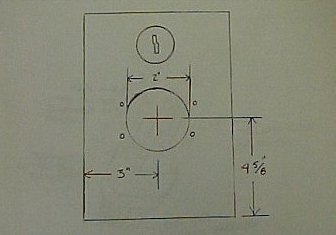

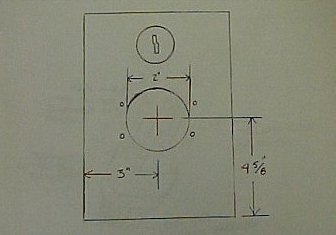

| 5. At this time the fuel door will need to be drilled to accept the new

switch.

Anyone with a good drill press could be able to accomplish this, but be

advised, a new fuel door without the lock mechanism is $180.00. I chose

to allow a machine shop to drill mine, it cost me $20.00, I think well

worth it. If you go this route take the new switch with you so it can be

aligned properly. |

|

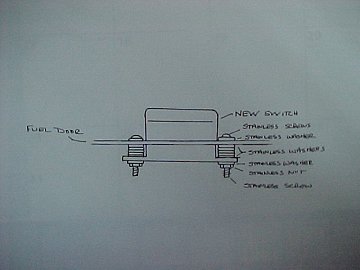

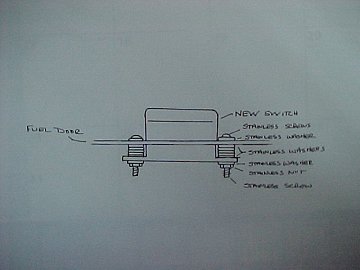

6. Now that the holes are drilled it would be a good time to decorate,

the door with the on/off/access decals if you so desire. After this is

done, attach the new switch using the SS screws, washers and bolts. The

connectors needed a little clearance so I shimmed them with 5 washers.

Cut the excess screw length off flush with the

nuts with a Dremell tool.

I did leave out, in the pic, the lock washer under the nut and the

thread glue. I also ran a bead of silicon around the outside of the

switch for waterproofing.

|

|

You can use Auto Grade "Blackout Tape" to add design

character to the fuel door, to further enhance the project.

7. Re-attach the fuel door, attach the new wiring to the connector on

the wiring harness side. Run the wires under the fuel door, connect the

Red one to the center prong, the orange one to left prong, and cover the

right prong with a spare connector

I'm going to use this leftover connection later for a cigarette lighter.

|

|

8. Close the fuel door, re-attach the seat and try the new switch out.

|

|

"Rasoul"

used flush mounted flat head screws for a clean, smooth topside

appearance. (Below)

|

|

|

|

Dick "Reno" took his switch project a

little further by moving it upward on the panel and adding a

fuel door lock catch to the switch post. Now the switch does

double duty! (Below) |

If you're interested in taking on a bit of metalworking to

achieve the double duty latch/switch function,

CLICK HERE to download Rasoul's follow-up PDF file of

the latch conversion process.

|

|

Materials Needed

|

Tools needed

|

1. 1 ft of 16ga. red wire

2. 1 ft of 16ga. orange wire

3. 2 16ga. inline connectors

4. 3 Quick disconnects

5. 28 #8 SS washers

6. 4 #8 SS internal tooth washers

7. 4 SS 8x24x1" machine screws

8. 4 SS 8x24 nuts

9. clear Silicon

10.1 Side Hinge Ig switch, Drag Specialties #DS 272187

11.Electric tape or shrink tubing

12.1 package of Resistors, Radio Shack #271-1311

13.Locktite

|

1. Wire cutters

2. 5&6 mm allen wrenches

3. Blade screw driver

4. Soldering iron & electrical grade solder

5. 10mm socket & ratchet

6. 8mm end wrench

7. Dremmel tool w/ a grinding wheel or a Hack saw to cut off the machine

screws

|

Many thanks to my cyber

friends Ronnie Cline, for the excellent How-To write-up and

photos,

and to "Rasoul" and "Reno" for the additional option photos for

this project!!

|

|