Going Nuts?

|

A Simple Solution To

Nagging, Loose Exhaust Header Nuts

|

|

One of the little idiosyncrasies of the LC is its tendency for the

rear exhaust header flange nuts to work loose, leaving the gate open for

air leakage at the joint, and increased exhaust popping. Torque it this

morning, ride it this afternoon, and torque it again tonight! Just can't

keep the nuts from working loose!!

Your nuts aren't coming loose. What's happening is the exhaust flange

itself, a cast aluminum piece, is warping under the heat and giving in

to the torque on the nuts, thus, they become "loose" without ever

moving.

If you continue to torque or tighten these "loosening" nuts, you will

eventually notice that the outer points of the flange will be getting

closer to the head metal. The closer they get, the harder its going to

be to remove that puppy, should it ever be necessary.

Assuming that the exhaust gasket is still working to properly seal the

joint, here is a SUGGESTION (I have not actually done this, but it is

what I would do in an effort to remedy the problem):

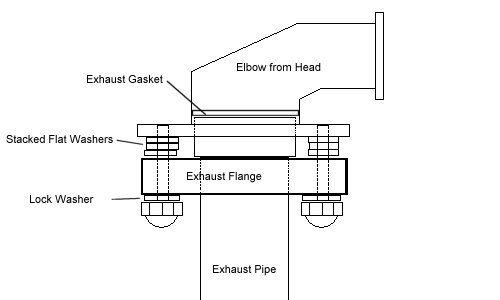

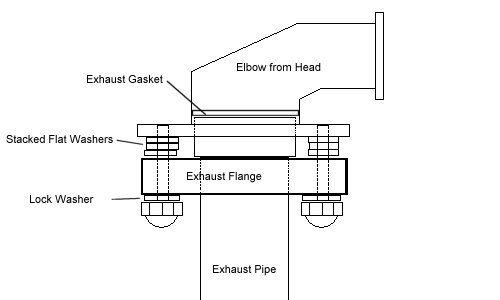

The flange has to compress the exhaust gasket against the head metal in

order to seal the joint, so all you need to do is create spacers to fit

between the flange and the head metal where the studs are. Make the

spacers just shy of the space between the flange and head, so that when

you torque the nuts, the flange bottoms out on the spacers under torque

specs. This will "fix" the flange in an unchangeable position, and

prevent it from warping under heat. Once the gasket is compressed, it

doesn't shrink, or change thickness, so there should not be a need to

re-torque or tighten the nuts further in the future. Use stainless lock

washers to prevent the nuts from coming loose.

Spacers could be cut from steel tubing and slipped over the exhaust

studs, or just stack some stainless washers on the studs between the

flange and head.

The rear flange on my LC warped its way all the way down to where the

farthest points actually touched the head (elbow piece). It never worked

loose after that, but I destroyed it trying to get it off when I changed

to Roadhouse pipes. The flange on the Roadhouse pipes was rather

unsightly, but was a thick flat piece of steel and it never worked loose

because the harder steel couldn't warp.

Just an untested idea, but it may be your best bet! If you try it and it

works, let me know and we'll declare it "tested". :-)

|

|